1. USE OF SYSTEM FV KLIMA

Ceiling cooling/heating FV KLIMA is modern energetically economical system of a surface area cooling. It´s made in several contruction variations adapted to various ceiling constructions.

Ceiling cooling/heating FV KLIMA is modern energetically economical system of a surface area cooling. It´s made in several contruction variations adapted to various ceiling constructions.

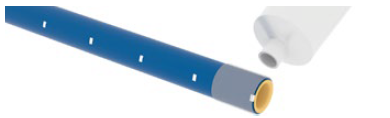

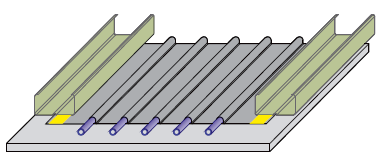

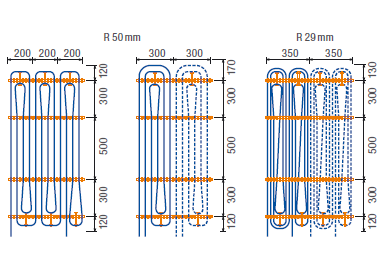

System consists of thin cooling registers CoolFLEX, which are placed in metal soffit cassettes. Registers CoolFLEX are tailored according to project specifications. Cooling performance is up to 75 W/m2.

SSystem consists of then cooling registers CoolFLEX, which are placed on plasterboard panels and it offers simple and safe mounting. For securing of maximal performance there are used plasterboard panels with increased thermal conductibility (including graphite). For docking the system uses standard metal contruction designed for plasterboard ceilings, using CD and UD metal profiles. Registers CoolFLEX are tailored according to project specifications. Cooling performance is up to 70W/m2.

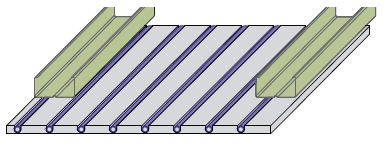

Cooling pipes are placed in plasterboard grooves. Individual active cooling panels CoolPLATE are tailored according to project specification. Active plasterboard panels are installed to standard metal contruction designed for lowered ceilings, using CD and UD profiles. Cooling performance is u to 60 W/m2.

CoolGRID cooling registers are located in the plaster ceiling. They are used in combination with core or gypsum plaster in a thickness of 10 - 20 mm. CoolGRID cooling registers are supplied pre-fabricated or directly mouted at workplace. The cooling performance is up to 70 W/m2 depending on the pitch and used plaster mixtures.

After assembly and checkout of whole system there is feeding of circuits with clear water according to following procedure:

Fittings assembly is made according to following working procedure. Along whole time of handling with fittings it is necessary to take precise care about cleanliness of the fitting and pipe as well, predominantly of their sealing parts.